From Sea to Shelf

With You at Every Step

LP Foods supply certified frozen seafood to buyers who need clear sources, solid partnerships, and real control over what they bring to market.

About Us

Confidence, Built In

From sourcing to shipping, we ensure confidence – with our certified facilities, transparent supply chains, and lasting partnerships built on quality.

100 Years of Seafood Expertise

From Europe to Asia, our roots run deep in seafood innovation, global trade, and trusted partnerships.

Our Products

Vannamei Shrimp

(Litopenaeus Vannamei)

Farmed in Vietnam and Indonesia – ASC and BAP 4* Certified

Organic

Black Tiger

(Penaeus Monodon)

Origin: Vietnam Responsibly Farmed Naturland, Bio Suisse

Premium Octopus

(Octopus Maya, Octopus Cyanus)

Origin: Indonesia, Mexico – Part of a Fishery Improvement Project (FIP)

FISH

Species: Snapper, Mahi Mahi, Grouper, Barramundi, Cobia

Origin : Indonesia – Part of a Fishery Improvement Project (FIP)

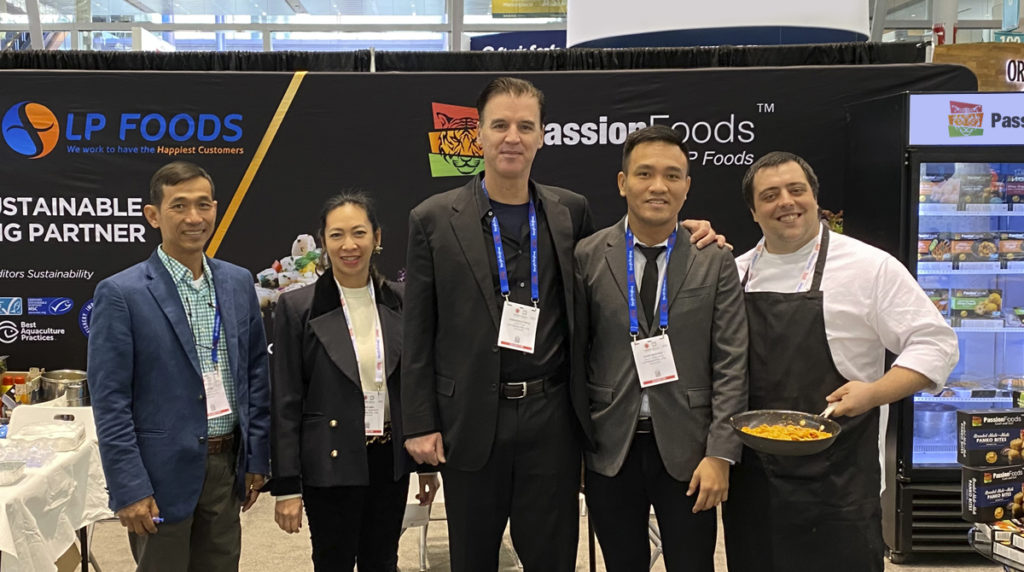

Passion Foods

Premium Seafood Value Added Products Developed by our experienced R&D Chefs

Quality Assurance

Experience You Can Trust Quality You Can Trace

Backed by decades of hands-on experience, our in-house quality control team works alongside globally certified partners to ensure every product meets the highest standards – at every stage.

Certified Where It Matters

Global standards, met in our facility.

Eyes on Every Detail

Hands-on quality, our team monitors every product with intention.

Clarity from Source to Shelf

Traceable. Transparent. Trusted.

Farmed Items:

Sea caught Items:

Factories:

What experience looks like

NON CHEMICAL AND RESPONSIBLY SOURCED SEAFOOD

For 3 generations we have supplied quality seafood to retailers and restaurant chains globally.

We offer a supply chains fully certified and professionally audited.

Take a close look to our product: we have developed a strong expertise In Octopus and Fish with our clients.

Years of experience

Export countries

Number of products

Thousand

MTs

News and Blog

Stay Ahead Of The Curve With Our Thought-Provoking Content

THE WEEK AHEAD – Market News and Updates

VASEP forecasts that seafood exports will continue its uptrend in the upcoming months due to robust demand from markets. The war between Russia and Ukraine…

Shrimp Welfare Project Partners with Thuan Phuoc Corp.,…

The Shrimp Welfare Project (SWP) is excited to announce a groundbreaking collaboration with Thuan Phuoc Seafoods and Trading Corporation (Thuan Phuoc Corp.), Labeyrie Fine Foods,…

SENA 2022: A Successful Event For LP Foods…

We would like to thank you for spending your time visiting our booth at SENA 2022. It was our pleasure as we enjoyed many inspiring…